High Quality Metal To Metal Seated Valve Ball And Seat Kit - Metal To Metal Ball Seat – Future Valve

High Quality Metal To Metal Seated Valve Ball And Seat Kit - Metal To Metal Ball Seat – Future Valve Detail:

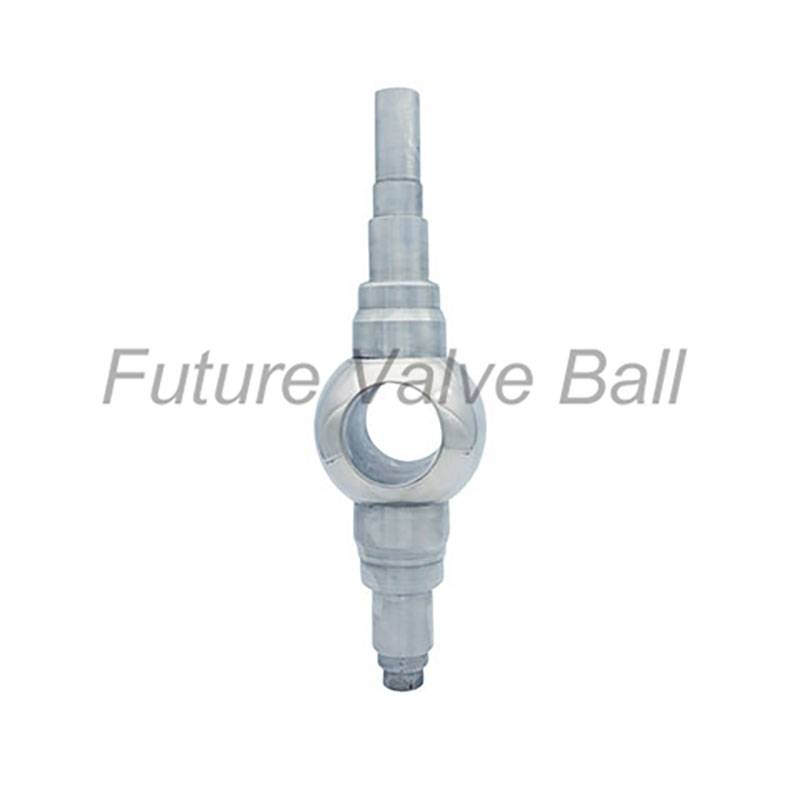

Metal seated valve ball and seat is the critical parts of metal seated ball valves. It is designed for extreme high pressure, temperature and abrasive conditions, such as cutting off or connecting solid granules, melted slurry, coal power, scalding cinder, steam water or other liquid etc. Therefore it has the feature of anti-static construction, extra tough coating, full bore and reduced bore, fire safe feature complying API607, and reliable sealing performance.

Metal Seat and Ball are made from base metals coated usually with hard chrome, tungsten carbide, stellite and Ni60. We have both thermal spray coating and cold spray coating available such as Laser Cladding, HVOF (High Velocity Oxy Flame)Coating, Oxy-acetylene flame spray, Plasma Spray process.

Ball and Seat Lapping

For metal seated ball and seat, we must provide complete valve ball+seat kits solution to customers because the ball and seat need lapping before being sent to serve. Over the years, We have developed a unique ball lapping technology for the coated ball and seat. Through simultaneous same and different direction of rotation, the ball and the seat result in perfect roundness and fitness, achieving “Zero Leakage”

Metal Seated Valve Ball Specification

Pressure Rating

Class 150LB-2500LB

Nominal Size

3/4” ~ 30”

Hardness:

HV 940-1100/HRC 68-72

Porosity

≦1%

Tensile strength

(≥70Mpa)

Heat Resistance

980℃

Leakage

Zero

Basic Materials

ASTM A105(N), A350 LF2, A182 F304(L), A182 F316(L), A182 F6A, A182 F51, A182 F53, A564 630(17-4PH), Monel, Alloy etc.,

Coating

Thermal Spray and Cold Spray:

Ni60,Tungsten Carbide, Chrome Carbide,

Stellite 6# 12# 20#, Inconel, etc

Product detail pictures:

Related Product Guide:

We've our have sales staff, style and design staff, technical crew, QC team and package workforce. We've strict excellent control procedures for each system. Also, all of our workers are experienced in printing field for High Quality Metal To Metal Seated Valve Ball And Seat Kit - Metal To Metal Ball Seat – Future Valve , The product will supply to all over the world, such as: belarus, Liverpool, Peru, Our business activities and processes are engineered to make sure our customers have access to widest range of products with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. We have people who embrace tomorrow, have vision, love stretching their minds and going far beyond what they thought was achievable.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.